Why Waste Treatment?

| The Problem | The Consequences | The Solution |

|---|---|---|

|

Untreated waste results in:

|

|

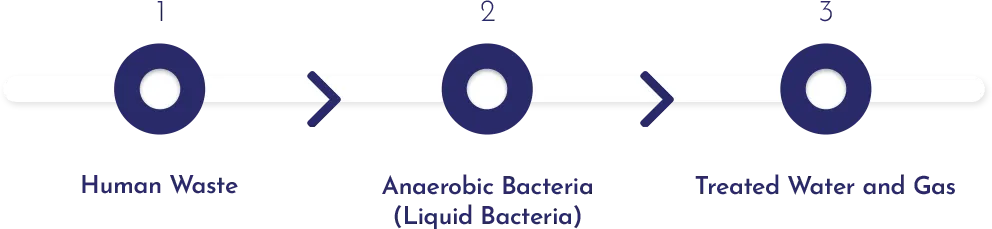

DRDO Bio-Digesters

Consist of two parts:

A specially designed and manufactured Bio-Digester Tank in rotomoulded LLDPE or fibreglass.

Anaerobic Microbial Inoculum (AMI) – the bacterial component.

NagMagic Bio-STP (Sewage Treatment Plant)

Two stage treatment process:

Stage 1: Anaerobic digestion using a Bio-Digester to treat the sewage. Effluent suitable for use in irrigation, gardening, civil construction, etc.

Stage 2 (Optional): Secondary treatment which makes the effluent compliant with CPCB norms. Effluent suitable for flushing toilets, etc.

Low on investment. High on performance. Very low running cost.

Minimal maintenance with only one-time addition of inoculum and NO de-sludging for the lifetime of the system.

All sewage/organic matter is 100% bio-digested and gets converted into treated gas and water.

Sealed system … NO contamination of ground water.

100% biological process. NO harmful chemicals used

Ideal for individual households, apartments, commercial establishments, educational institutions, etc.

Bio-STP System

Performance Results of Bio-STP and Bio-Digester Systems

| Sr. No. | Parameter | CPCB/MPCB* Standards For | NagMagic Results Range | ||||

|---|---|---|---|---|---|---|---|

| Inland Surface Water | Public Sewers | Land for Irrigation | Marine Coastal Areas | Bio-Digester Effluent | Bio-STP Effluent | ||

| 1 | Suspended Solids mg/l (max) | 100 | 600 | 200 | 100 | 100 - 150** | 30 - 50 |

| 2 | pH Value | 5.5 - 9.0 | 5.5 - 9.0 | 5.5 - 9.0 | 5.5 - 9.0 | 6.5 - 7.5 | 6.5 - 7.5 |

| 3 | Biochemical Oxygen Demand [3 days at 27 degrees Celsius] mg/l (max) | 30 | 350 | 100 | 100 | 80 - 100 | 20 - 30 |

| 4 | Chemical Oxygen Demand mg/l (max) | 250 | - | 250 | 250 | 180 - 200 | 40 - 50 |

| 5 | Fecal Coliform Count (CFU/100 ml) | 1000 | - | - | - | 250 - 300 | 50 - 100 |

** Inorganic Suspended Solids are a function of the input quality of water

Rotationally Moulded Bio-Digester Tank Capacity Chart

| Sr. No. | Bio-Digester Tank Size (litres) | No. of Users in Domestic Setting | No. of Users in Industrial Setting | Bio-Digester Tank Dimensions | AMI Required (litres) | |

|---|---|---|---|---|---|---|

| Dia (mm) | Height (mm) | |||||

| 1 | 700 | 4 to 6 | 8 to 12 | 1,100 | 1,015 | 200 |

| 2 | 1,000 | 6 to 10 | 12 to 20 | 1,100 | 1,385 | 300 |

| 3 | 1,500 | 10 to 20 | 20 to 40 | 1,210 | 1,670 | 450 |

| 4 | 2,000 | 20 to 30 | 40 to 60 | 1,425 | 1,600 | 600 |

| 5 | 2,400 | 30 to 35 | 60 to 70 | Two 700 litre tanks combined with one 1,000 litre tank | 700 | |

| 6 | 3,000 | 35 to 45 | 70 to 90 | 1,680 | 1,665 | 900 |

| 7 | 3,500 | 45 to 55 | 90 to 110 | Two 1,000 litre tanks combined with one 1,500 litre tank | 1,000 | |

| 8 | 5,000 | 55 to 80 | 110 to 160 | Two 1,500 litre tanks combined with one 2,000 litre tank | 1,500 | |

| 9 | 7,000 | 80 to 120 | 160 to 240 | Two 2,000 litre tanks combined with one 3,000 litre tank | 2,100 | |

Fiberglass Reinforced Plastic (FRP) Bio-Digester Tank Capacity Chart

| Sr. No. | Bio-Digester Tank Size (litres) | Bio-Digester Tank Dimensions (cms) |

No. of Users in Domestic Setting | No. of Users in Industrial Setting | AMI Required (litres) |

|---|---|---|---|---|---|

| 1 | 700 litres | 83 x 83 x 100 | 4 to 6 | 8 to 12 | 200 |

| 2 | 1,000 litres | 100 x 100 x 100 | 6 to 10 | 12 to 20 | 300 |

| 3 | 1,200 litres | 120 x 100 x 100 | 11 to 14 | 15 to 30 | 360 |

| 4 | 1,500 litres | 150 x 100 x 100 | 10 to 20 | 20 to 40 | 450 |

| 5 | 2,000 litres | 150 x 150 x 100 | 20 to 30 | 40 to 60 | 600 |

| 6 | 3,000 litres | 200 x 150 x 100 | 30 to 35 | 60 to 70 | 900 |

| 7 | 4,000 litres | 200 x 200 x 100 | 35 to 45 | 70 to 90 | 1,200 |

| 8 | 5,000 litres | 220 x 200 x 120 | 45 to 55 | 90 to 110 | 1,500 |

| 9 | 6,000 litres | 300 x 200 x 100 | 55 to 80 | 110 to 160 | 1,800 |

| 10 | 7,000 litres | 350 x 200 x 100 | 80 to 120 | 160 to 240 | 2,100 |

| 11 | 8,000 litres | 400 x 200 x 100 | 120 to 140 | 240 to 280 | 2,400 |

| 12 | 10,000 litres | 450 x 200 x 120 | 140 to 180 | 280 to 320 | 2,700 |

| 13 | 15,000 litres | 600 x 220 x 120 | 200 to 250 | 360 to 500 | 4,500 |

The monthly average running/operating cost of a 5 KLD (kilolitres per day) conventional STP is ₹5.70 – ₹6.30 per litre.

The monthly average running/operating cost of a 5 KLD NagMagic Bio-STP is ₹0.55 – ₹0.65 per litre.

The tanks for the Bio-STP systems are available in both rotational moulding and FRP.

The smallest system available can be used by 4 to 6 users in a domestic setting and 8 to 12 users in an industrial setting.

Theoretically, there is no upper limit for the number of users for a Bio-Digester tank.

Testing Facilities – Full Fledged Micro-Biology Lab

Autoclave (Sterilizer)

Data Logger on Bacteria Generation Plant (BGP)

Gas Chromatography

Gassing Manifold

Incubator

Laminar Hood

Muffle Furnace

pH Meter

Autoclave (Sterilizer)

Bacteria Generation Plant

Gas Chromatography

Gassing Manifold

Key Customer Segments

Corporates – CSR activities and for own use

Export Customers – NGOs, Corporates, etc.

Government and Semi-Government Institutions

NGOs, Civil Society Organisations

Retail

For more information please visit http://biodigester.in/