How K. K. Nag Private Limited Supports the Automotive Industry with EPP Solutions

The automotive industry has always been at the cutting edge of technological advancements, where safety, performance and efficiency are paramount. In the pursuit of designing better vehicles, the role of materials in improving functionality is critical. Such materials include polymer foams, with Expanded Polypropylene (EPP) being the most superior. As the first polymer manufacturer in India to introduce EPP, K. K. Nag Private Limited has been at the heart of this innovation, driving change and meeting the evolving demands of the automotive sector.

Table of Contents

Automotive Applications of K. K. Nag Private Limited’s Foam Solutions

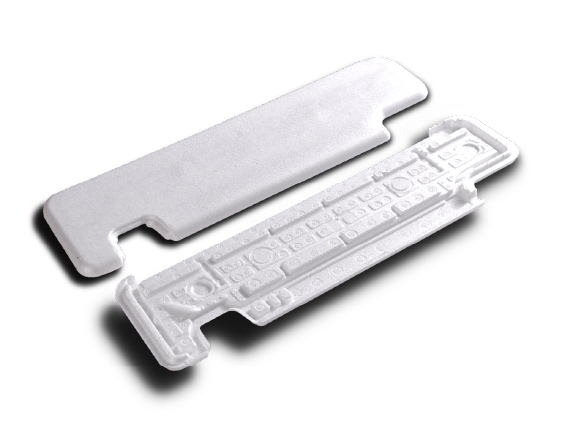

Force Motors Tool Kit

In June 2023, Force Motors approached K. K. Nag to develop an EPP tool kit for their new vehicle models, as the leather bags previously used for storing tools caused damage and generated noise during transit. Our team built a custom-fit EPP tool kit, ensuring each tool had a dedicated slot that prevented movement and eliminated noise. Recognising that a majority of the tools were shared across multiple Force Motors models, we adapted the prototype to fit tools for the FML Gurkha, FML Trax and FML Urbania vehicles into a single versatile kit. This solution showcases our unwavering dedication to quality and customer satisfaction.

Second Row Seat for TM Seating

We also provide innovative solutions for vehicle interiors. Our team developed a lightweight EPP seat core for TM Seating’s second-row seats. The solution used insert moulding to directly mount the seat core on the Body in White (BIW). Consequently, the vehicle’s weight was reduced by 6 kg, and it achieved improved fuel efficiency as well as lower emissions. The seat also has an anti-submarine effect, which enhances the safety of passengers in case of an accident. This product development reflects our focus on performance and safety, which are two essential pillars in modern automotive design.

Energy Absorbers for Toyota

Energy absorption is the most important aspect of vehicle safety. We developed EPP bumper cores for Toyota that are engineered to provide superior impact resistance. Additionally, the lightweight and high-strength properties of EPP enhance overall vehicle performance and efficiency, aligning perfectly with Toyota’s commitment to safety and innovation.

Sun Visors

Sun visors are one of the most difficult components to mould due to the extremely low thickness of the product and the superior surface finish required. Our team co-developed lightweight, bespoke sun visors with our customer to enhance the fit, feel and finish, as well as to facilitate modern features like LED lights and mirrors. EPP sun visors are now being widely preferred over sun visors made of hard plastics.

Advantages of EPP Automotive Components

K. K. Nag Private Limited’s foam solutions offer a wide range of benefits in terms of performance, cost and sustainability.

Functional Design

EPP’s exceptional lightweight properties significantly reduce vehicle weight, enhancing fuel efficiency, lowering emissions and improving overall performance. Its precisely engineered framework ensures each component achieves an optimal strength-to-weight ratio for superior functionality.

Customisation

Customisation is one of the most outstanding features of our foam solutions. We work closely with automotive manufacturers to understand their unique requirements, delivering precision-engineered foam solutions tailored to each application. This ensures that every product, whether a tool kit, seat core or energy absorber, meets and exceeds expectations.

Sustainability

Today, sustainability is the common goal of most industries worldwide. We ensure that we employ green EPP manufacturing processes at our GreenCo-certified plant in Pune. Thus, K. K. Nag Private Limited assists automotive manufacturers in achieving their sustainability goals without sacrificing quality and performance.

Manufacturing Innovations

Not only do we innovate with product development but we also invest heavily in excellent manufacturing facilities. Our in-house tool room helps with rapid prototyping and precision tooling for every product, ensuring high-quality output. Advanced foam moulding techniques and material development capabilities allow us to stay ahead of the competition and provide solutions to evolving automotive standards.

Real-world Collaborations

At K. K. Nag Private Limited, we believe that successful product development is a collaborative process. By working closely with automotive manufacturers, we address their specific challenges. Our value engineering capabilities and extensive expertise in EPP empower us to deliver high-performance products that ensure stakeholder satisfaction and project success.

The Future of Foam in Automobiles

The future of expanded polypropylene foams in the automotive industry is very promising. As more consumers demand lightweight materials, we will be at the forefront of the industry’s transformation into electric and autonomous vehicles. Once again, our foam solutions will play a central role in these emerging technologies, ensuring excellent efficiency and safety of modern vehicles.

Take Your Automotive Designs To The Next Level!

As the automotive industry continues to evolve, it is time to partner with the most experienced polymer manufacturer in India for custom foam solutions. K. K. Nag Private Limited ensures that automotive manufacturers are ahead of the curve by providing vehicles that meet the highest performance, safety and environmental responsibility standards.

Unlock the future of automotive innovation with K. K. Nag Private Limited’s custom EPP solutions!