Engineering Support Division

Our Engineering Support Division provides end-to-end engineering support to all our plastic processing plants. We maintain a well-equipped tool room in Urse (near Pune) that handles the entire engineering process, which involves:

- Development of concept to meet customer expectations

- Designing of products

- Development of prototypes

- Reverse Engineering

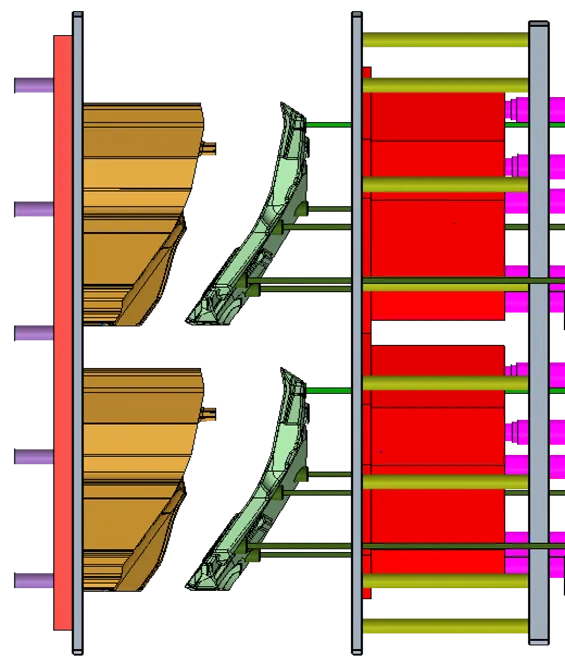

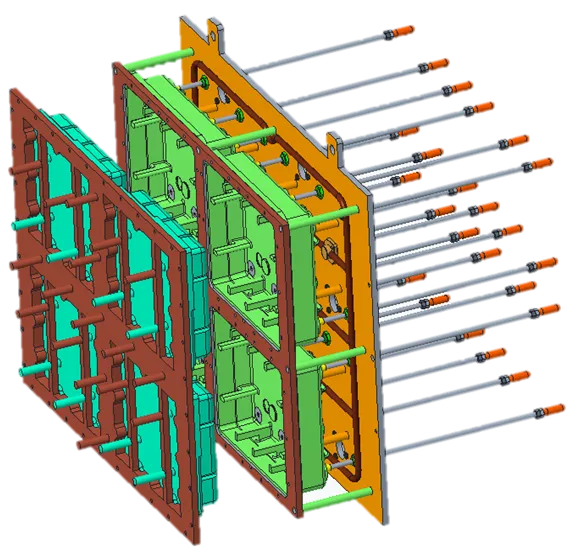

- Designing of moulds

- Mould Manufacturing (Expanded Polystyrene, Expanded Polypropylene, Rotationally moulded and Injection moulded products)

- Development of jigs and fixtures

- Engineering value add services

What Makes Us Unique

- World class capability to design and manufacture a wide range of tools – multi-cavity moulds and repeat tools for interchangeability of components.

- Synergistic team of highly experienced and skilled designers, engineers and workmen.

- Innovative solution providers with a rich history (five decades) of providing pioneering engineering solutions.

- Well-developed infrastructure and vendor base for all mould manufacturing related activities.

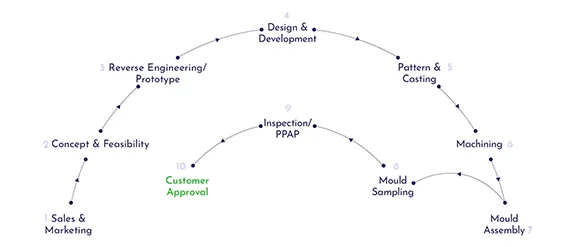

Our Process

Since all the activities are carried out by our in-house team of experts, we have complete control over the entire tool making process. This gives us great flexibility with regard to lead times and it also ensures that all technological upgradations are immediately implemented in our moulds.

We have an experienced and talented team of engineers who ensure the highest quality at different stages of the mould manufacturing process. Our engineers routinely receive training overseas and are exposed to the best practices internationally.

The Engineering Support Division is the backbone of our plastic processing operations.

What We Offer

- Total tooling solution – One stop shop

- Superior quality moulds

- Value added services

Our Facilities

- Engineering and CAD centre

- General and precision machining

- CNC machining

- Inspection and calibration

- Fitting and assembly

Prototype Development

CFT Design Review

Pattern Development

Machining

Fabrication

Mould Assembly

Product CMM Inspection