Our Tryst with Thermocole

Our association with Expanded Polystyrene (EPS) or Thermocole actually predates the company itself.

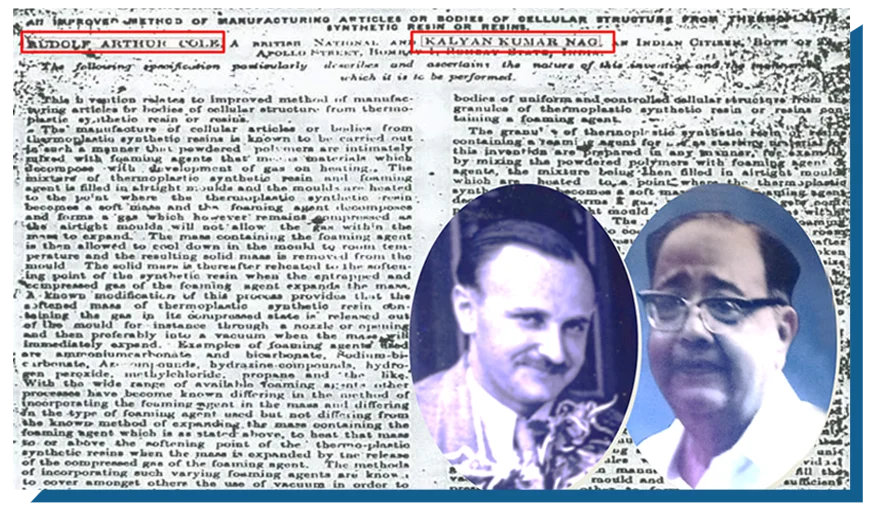

Prior to starting K. K. Nag Pvt. Ltd, Mr Kalyan Kumar Nag was a partner at R. A. Cole & Co. It was during Mr Nag’s stint there that his partner, Mr R. A. Cole, and he, developed EPS resin for the first time in India. They named the product Thermocole – “Thermo” for heat and “Cole” for Mr R. A. Cole – and that is now the generic name for Expanded Polystyrene in India!

Shown below is a copy of the original Indian Patent for Expanded Polystyrene (Thermocole):

Our Journey

We were one of the first companies in India to manufacture products out of Fibreglass Reinforced Plastic (FRP) at a time when the use of composites was in its infancy. The high strength to weight ratio of FRP, and its anti-corrosive properties, revolutionised many applications including the making of helmets and the handling of corrosive media in areas such as the chemical process industry.

We started processing Expanded Polystyrene (EPS) in the early 1970s. As the consumer electronics and appliances industries started developing, we grew with them by custom designing EPS packaging for various new products. In those days, the number of OEMs in the consumer electronics sector were few, as were the number of processors of EPS. It is interesting that the designs of some of the products that the pioneers in the consumer electronics and appliances industries developed, notably Mixers, are still being copied by the new players; and just as the designs of the appliances are still being used today, so are the designs of the EPS packaging for those products, which were originally developed by us!

Additionally, we were the first company in India to introduce Expanded Polypropylene (EPP) in the 1990s. In layman’s terms, EPP can be thought of as “Thermocole Plus”, because it has the same cushioning properties as EPS but is much more durable and regains its original shape after impact. It is now widely used in the automobile industry because, not only does its shock absorption characteristic improve safety, but the lightweight reduces the weight of the overall vehicle considerably and thus improves its fuel efficiency.